vertical flame spread experiments and modeling

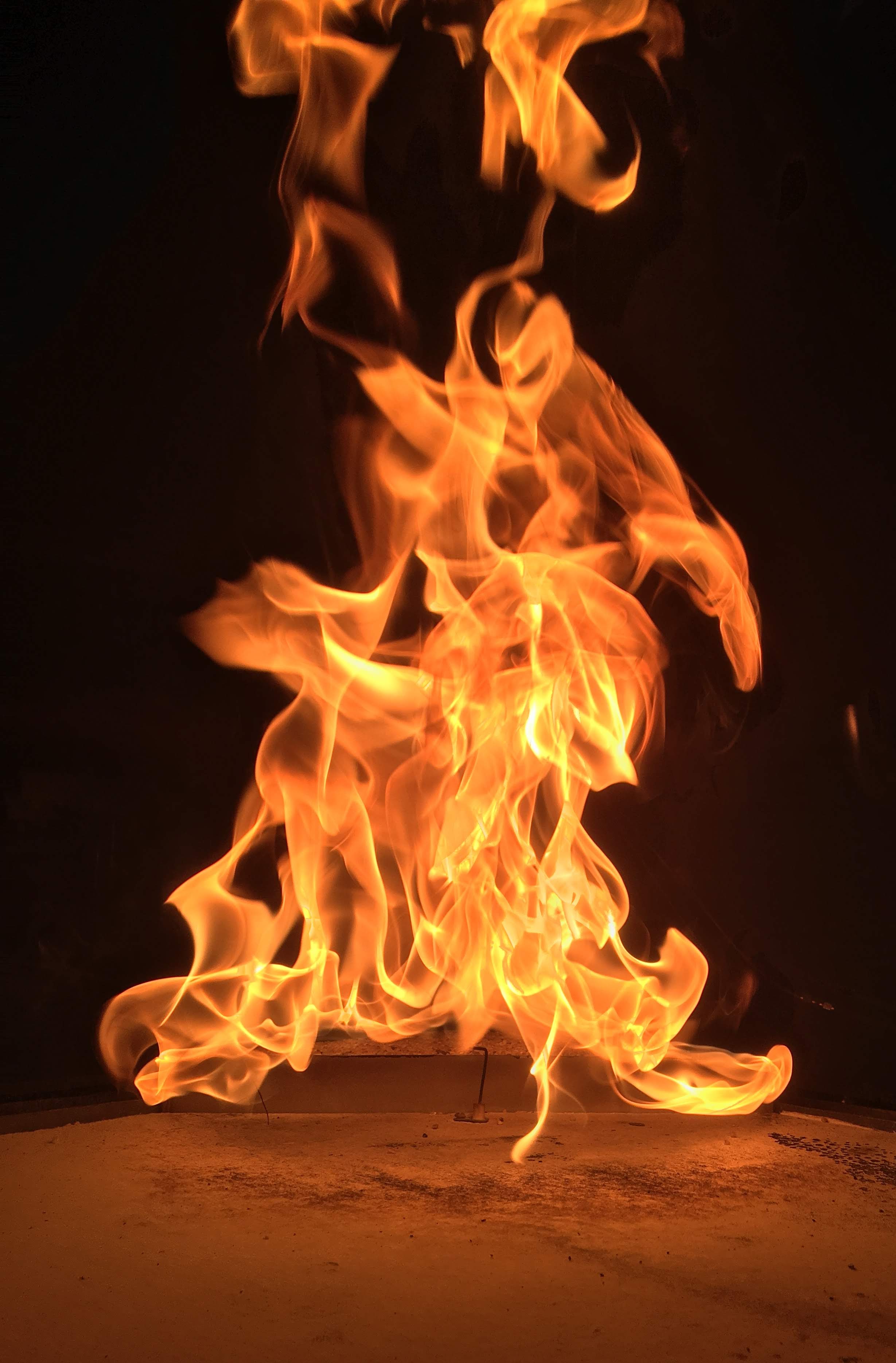

Single Burning Item (SBI) Corner flame spread scenario

Corner fires are more hazardous than open wall fires due to the restricted geometry. The geometrical constraints cause corner flames to have longer flame lengths and more hazardous due to increased radiative feedback between the two adjacent walls. Thus, corner fires on combustible material serve as a severe test for the materials before they are employed in commercial applications. Developing prediction capability of fire hazard in such scenarios is important to assist material development, screening, and testing.

Poly(Methyl Methacrylate) (PMMA) is probably the most widely used polymer in fire research. It’s application in commercial industry is enormous as it behaves as a relatively cheap, transparent and lighter substitute for glass. But due to it’s combustible nature, it has been utilized to study fire spread scenarios such as mass burning rate, incident flame heat flux in small test setups which replicate laminar flames.

PMMA exhibits thermal degradation that is non-charring, non-swelling, and primarily emanates gases having chemical composition of it’s monomer. This simplifies the pyrolysis model development issues and several research groups have developed pyrolysis model for PMMA thermal degradation. This advantage of having a resolved condensed phase decomposition scheme, PMMA is an ideal material for understanding the fundamental dynamics of flame spread in corner scenarios.

This research project is focused on studying flame spread in corner fire over PMMA so as to experimentally measure crucial parameters that primarily govern the flame spread phenomenon, namely heat release rate (HRR) via oxygen consumption calorimetry, well-resolved flame heat fluxes during the flame spread process, and emissions at 900 nm narrowband to observe emissions from soot (a primary emitter at this wavelength). The wealth of collected data can be used for validation of sub-models used in Computational Fluid Dynamics (CFD) models. The objective also involves developing an empirical flame feedback model and developing a semi-empirical flame spread model to predict HRR evolution during the flame spread process.

Check out more information in the full publication (Chaudhari et al., 2021).